Programming Services

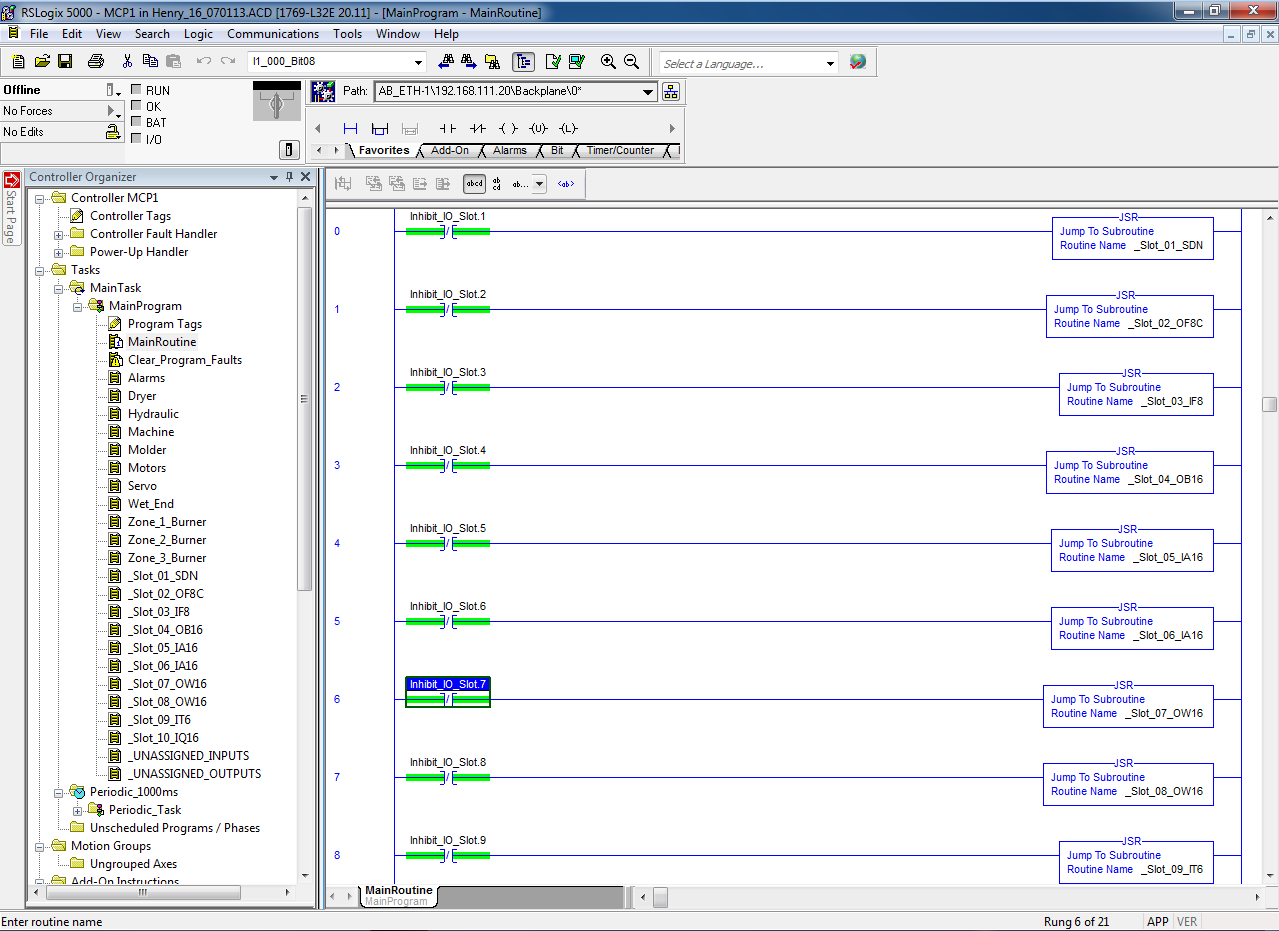

Our primary focus is programming services, and we

regularly provide programming support for systems integrators and OEMs

on projects large and small. Whether working as part of a team on a

multi-million dollar plant upgrade, or designing and developing a small

machine, we work to define and meet the customer's requirements. This

often includes assisting in initial scope definition and documentation. |

|

System Upgrades

We have helped specify and implement a number of

machine upgrades to vintage equipment that is still viable. This

extends the life of capital equipment, and usually improves performance

as well. Upgrades typically involve replacing or adding a new PLC

system, converting the old program or relay logic with new code, and

replacing arrays of buttons and indicators with user-friendly

touch-screen interfaces. Since downtime must be kept to a minimum when

upgrading equipment that is actively being used, we work with the

customer to create and meet a reasonable installation schedule. |

|

Onsite

Troubleshooting and

Startup

We have a strong background in onsite work,

and can

assist in making equipment perform, whether we designed the system or

not. From the ideal (drawings up-to-date, programs well-documented) to

the less-than-ideal (PLC fried in a power surge with no back-ups or

drawings), we have seen the spectrum and are able to deliver.

|

|

|